Gas-tight cold store crucial prior to storage

A much-discussed topic that can cause problems during the storage season:

The gas-tightness of a cold store. A cold store that is not 100% gas-tight, needs regular nitrogen support to maintain the low oxygen level. And thus unnecessary costs. Especially with the current energy prices a cost item to be aware of. And last but not least, loss of quality of the product.

It is therefore worth the effort to test the empty stores before the storage season and to detect and solve any leaks. Prior to this, a number of things should already be on point:

- Gas-tight connectors at the various connections to the cold store;

- Gas-tight coating on all corners and joints;

- Gas-tight doors, suitable for CA/ULO storage;

- Correct gas-tight finish of other risk areas such as suspension points, hatches, under and overpressure valves, pressure compensation lungs, siphon of condensation water discharge from the cooler/evaporator, etc.

Perhaps through experience of past season, it can be pointed out which cold stores need the most attention. The stores where the greatest effort had to be made to achieve low oxygen levels. A cold store can then be tested in various ways. A distinction has to be made here between testing a store for gas-tightness on the one hand and searching for leaks on the other.

Store test

Before performing a store test, we recommend that the stores are empty and the temperature inside and outside the store is the same. Changes in temperature inside and outside the store affect the air pressure. Air contracts or expands and panels move, affecting the reading.

Cooling the store could be an option, because materials then behave in the same manner as they do during the actual storage. However, we advise not to during the store test, but only during the leak search. In addition, we recommend leaving the stores next to the store to be tested empty during the test, so that leakages between stores can also be observed.

A store behaves differently when in overpressure compared to under-pressure. It is therefore best to test both during overpressure and under-pressure.

- Negative pressure test

The store can be brought to a negative pressure with a vacuum cleaner. During the under-pressure test, the door, hatches, sealing caps, etc. are sucked against the panels. The panels come closer to each other as well. This can give a false image because some leakages may not occur. A negative pressure test has the advantage that the store can be easily examined from the inside. The risk areas can be checked for leaks and penetrating air bubbles by the use of soapy water. - Over-pressure test

With the aid of an aeration fan, a store can easily be brought to over-pressure. In an over-pressure condition, the door, hatches, closing caps, panels, etc. are pushed outwards and leaks can occur that do not exist during the negative pressure test. During the actual storage, a store is at over-pressure, so an over-pressure test is definitely recommended.

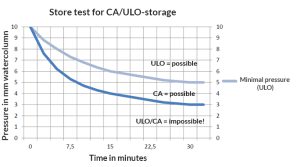

The store must be pressurized to a pressure of 10 mm water column. The gas-tightness can be determined by reading the pressure-drop after 30 minutes.

The pressure should still be at least 5 mm water column after 30 minutes. If this is not the case, it is impossible to maintain ULO levels.

Over-pressure leaks can often be found close to the door. Panel joints can also cause issues in old cold stores. Use soapy water again to find/detect leaks.

Some leaks are more difficult to detect on the outside of the store, so it is recommended to use both methods. Always make sure to check beforehand whether the under- and over-pressure valves are functioning properly.

Any leaks can be resealed with gas-tight coating.

Leak tightness CA-system

Leaks in the CA system can of course also play tricks during the storage period. Therefore, also check the following parts:

- Sealing of under- and overpressure valves;

- Pressure compensation lungs of the stores and CO2 Adsorber;

- The piping network of the CO2 Adsorber. This can be tested separately, using the special connections on our machines;

- If present, the piping network of the ethylene decomposer.

A much-discussed topic, which unfortunately does not always get the focus it deserves. It takes some time, but with relatively few resources it can save a lot of worries and unnecessary costs.

For more information, please contact us:

☎ +31 229 212 154 ✉ sales@besseling-group.com